Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Implementation of Site Quality Management System for a Small-Scale Building Construction Project Sites

Authors: Tejal Vishe, Prof. R. Mahadeva Swamy, Dr. Yashvant Patil

DOI Link: https://doi.org/10.22214/ijraset.2024.63024

Certificate: View Certificate

Abstract

The construction industry plays a vital role in consistently delivering value and quality to clients, yet grapples with challenges related to quality, resulting in suboptimal outcomes, unsafe structures, and budget overruns. To tackle these issues, the establishment of a Quality Management System (QMS) becomes crucial. This systematic approach ensures both product and process quality, satisfying clients, adhering to regulations, and minimizing rework and waste. The effective implementation of a robust QMS involves various tasks, including business analysis, initial planning, awareness raising, expert training, document control, deployment, measurement and control, auditing, and continuous improvement. This research specifically explores the significance of quality management in small-scale construction projects during the execution phase. Data gathered through interviews and questionnaires with builders/contractors, consultants, and customers/building occupants inform the study, aiming to shed light on the quality management practices of small-scale contractors and their impact on customer satisfaction, operational efficiency, and cost-effectiveness.

Introduction

I. INTRODUCTION

In today's highly competitive construction market, it is vital for construction firms to consistently provide top-notch quality and genuine value to their clients. Building strong client relationships, fostering teamwork, and delivering high-quality work are primary objectives. The key to achieving these goals lies in implementing a Continuous Improvement (CI) process, forming the bedrock of quality management.

Quality holds paramount importance in the success of construction projects, directly impacting the satisfaction of all project participants. Despite the significance, the Indian construction industry has long grappled with quality issues, with a notable portion of infrastructure project budgets affected. Contractors, at times, secure contracts with low-cost bids, compromising work quality. Similarly, consultants may face pressure to cut initial construction costs, resulting in subpar outcomes. This lack of quality manifests in poor workmanship and unsafe structures, leading to defective construction.

Engaging consultants for limited construction services can heighten risks and overall project costs, including disputes and delays. The absence of initial quality may also elevate long-term maintenance costs. Quality management assumes a pivotal role in all stages of a construction project's life cycle, defined by how well a product or service meets customer expectations. Quality Management Systems (QMS) ensure consistent delivery of products or services exceeding customer expectations.

The advantages of a robust Quality Management System are manifold, encompassing enhanced customer satisfaction, regulatory compliance, reduced rework and waste, data-driven decision-making, and an engaged workforce focused on continuous improvement. QMS implementation impacts various organizational departments and processes, fostering cross-functional communication and unity.

To underscore the significance of quality management in the execution phase of construction projects, this research aims to illuminate challenges and solutions in the construction industry. Developing and implementing a Quality Management System is a substantial undertaking demanding time and resources, yet the potential benefits are substantial.

Quality-One provides tailored support for organizations seeking to establish and implement a robust Quality Management System, offering consulting, training, and expert support. The concept of Total Quality Management (TQM) underscores the involvement of all organization members in creating and maintaining product and service quality. TQM strives for quality by meeting customer needs, continuous process improvement, and involving everyone in quality management.

Quality improvement techniques like check-sheets, checklists, histograms, Pareto analysis, cause-and-effect diagrams, scatter diagrams, and flowcharts are essential tools for reducing variability and achieving quality.

In summary, the construction industry must prioritize quality to meet evolving client needs and stay competitive. Implementing a Quality Management System and utilizing quality improvement techniques are crucial steps toward achieving excellence in construction projects.

II. LITERATURE REVIEW

The examination of literature in construction management has focused on understanding the causes of quality defects, with a primary goal of defining the functions and significance of Construction Quality Assurance and Control. Albert P.C. Chan and C.M. Tam (2000) conducted a study in Hong Kong, analyzing 110 building projects, identifying project management actions, construction team leader effectiveness, client's quality emphasis, and time emphasis as key influencers on project quality. Their findings contribute to a predictive quality performance model with implications for national and international applications. Another study by Samiaah M. Hassen Al-Tmeemy, Hamzah Abdul-Rahman, and Zakaria Harun (2011) explores contractors' perceptions of quality cost systems in Malaysian construction projects, emphasizing the role of enhancing quality awareness and addressing cultural, systemic, and company-related barriers.

Run-Run Dong (2017) introduces the application of Building Information Modelling (BIM) technology in construction quality management and talent training to overcome challenges in construction technology. This paper highlights BIM's advantages over traditional methods and its role in addressing quality issues in housing construction projects. P.P. Mane and J.R. Patil (2015) emphasize the interconnectedness of quality management within construction projects, introducing a comprehensive Quality Management System (QMS) covering planning, assurance, and control. Ahmad Rashed and Mohammad Othman (2015) investigate the implementation of Total Quality Management (TQM) in the construction sector in the West Bank, recognizing TQM's potential benefits in revitalizing the economy.

Sergey Lukichev and Marina Romanovich (2016) address the challenges of developing Quality Management Systems (QMS) for construction companies, emphasizing the importance of QMS in sustaining construction businesses and outlining a process for implementation. Ivanov Nikolay's research (2016) discusses the optimization of nonconformities management cost in the QMS of small-sized enterprises, introducing a corrective action plan ranking algorithm to minimize costs related to nonconforming products during economic downturns.

Mohd Zaid Malik, Rajiv Banerjee, and Syed Aqeel Ahmad (2018) review the implementation of Total Quality Management (TQM) in the construction sector, focusing on its proactive approach and potential benefits in improving overall quality, customer satisfaction, and organizational effectiveness. Aawag Mohsen Alawag, Wesam Salah Alaloul, and M.S. Liew (2021) emphasize the importance of TQM in enhancing the quality of output in the construction industry, specifically in Malaysian Industrialized Building System (IBS) projects, introducing a conceptual framework with leadership, customer satisfaction, and continuous improvement as crucial factors for high-quality IBS projects and overall organizational performance improvement in Malaysia. These studies collectively contribute to a comprehensive understanding of quality management in the construction industry.

III. RESEARCH METHODOLOGY

In examining a construction project, individuals often rely on presented quality specifications, trusting in the assurances provided by glossy brochures. However, if concealed quality defects exist in the construction process, it constitutes a breach of trust by contractors and can lead to severe consequences, including building collapses. Swift action is imperative to rectify quality maintenance failures in the construction industry.

Effectively addressing this challenge involves thoroughly investigating root causes and proactively adopting preventative measures to minimize defects. Decisive actions and their prompt implementation are crucial to reducing the occurrence of quality maintenance issues.

Understanding the chosen methodology is crucial, as it equips individuals with the skills to grasp its significance and interpret research data accurately. Research methodologies serve as guiding tools for unravelling complex problems, providing necessary training to apply them effectively in addressing real-world issues.

In the context of establishing a Quality Management System for construction sites, the research methodology assumes a central role. It elucidates the foundational philosophical principles underpinning selected research methods, whether qualitative, quantitative, or a combination of both. The methodology encompasses various research techniques, including literature review, publication research, interviews, surveys, and data collection methods.

The focus is on delving into the existing Quality Management System, understanding factors impacting construction project quality, and uncovering flaws within Quality Management during project execution. Practical strategies for rectifying these issues are aimed to be devised based on collected data.

The research methodology involves sequential steps:

- Commence with an extensive literature survey, reviewing journals and quality standards.

- Use insights gained to identify factors influencing quality management.

- Construct a tailored questionnaire addressing identified factors.

- Disseminate questionnaires and schedule interviews with contractors to delve into primary challenges.

- Meticulously examine and interpret collected data.

- Devise recommendations and solutions based on analysed factors, with the goal of benefiting contractors.

The questionnaire survey includes multiple optional points requiring a five-point rating scale. The scale is defined as follows: "5= Extremely Strong, 4= Strong, 3= Moderate, 2= Less, and 1= Very less." It includes Yes/No questions and a few open-ended descriptive questions.

In conclusion, a meticulously structured research methodology forms the foundation of this study on the Quality Management System for construction sites. It ensures a systematic, rigorous research process that generates valuable insights into challenges and opportunities within the construction industry, contributing to improved quality management practices.

IV. DATA COLLECTION & ANALYSIS.

The central aim of this study is to delve deeply into quality management practices within the construction sector, seeking avenues to enhance the quality of construction projects. The questionnaire's design stems from a synthesis of insights garnered from extensive literature reviews and the practical experiences of field experts, comprising contractors, engineers, project managers, and consultants, possessing valuable insights into factors influencing construction quality.

With a specific emphasis on the execution phase, especially the superstructure, the questionnaire targets critical elements like column work, beam work, slab work, brick, or block work, and plastering work. While acknowledging various factors impacting construction quality, the questionnaire specifically addresses pivotal elements such as concreting work, workforce competence, material and equipment quality, and detailing.

Employing a diverse array of question types, including Yes/No questions, scaled questions, and contingency questions, the questionnaire serves as a pivotal research instrument to gather information from respondents. Questionnaires, often geared towards statistical analysis, may incorporate scoring mechanisms to aggregate responses and gauge attitudes and opinions.

The questionnaire encompasses a wide spectrum of factors and practices relevant to quality management in construction, aiming to provide a comprehensive view without duplicating specific sources. Ultimately, the gathered data will be employed to rank Quality Control measures, Factors Affecting Quality, and Important Aspects using the Impact Index. Calculated as the sum of the product of frequency and the total number of responses, the Impact Index aids in identifying factors with the most significant impact on defects, ranking them accordingly.

Impact Index (I.I) is calculated as follows:

Impact Index = (∑F r x r/N)

Where: -

- r = severity score (Low=1, Medium=2, High=3)

- F = frequency of factors receiving a score of r

- N = total number of respondents

V. DISCUSSIONS & FINDINGS

In adherence to the research methodology, the provided survey questionnaires were distributed among participants involved in the construction project, encompassing their experiences and positions outlined in the preceding section. The survey garnered responses from 107 participants, and subsequent analysis of the data yielded the following detailed findings.

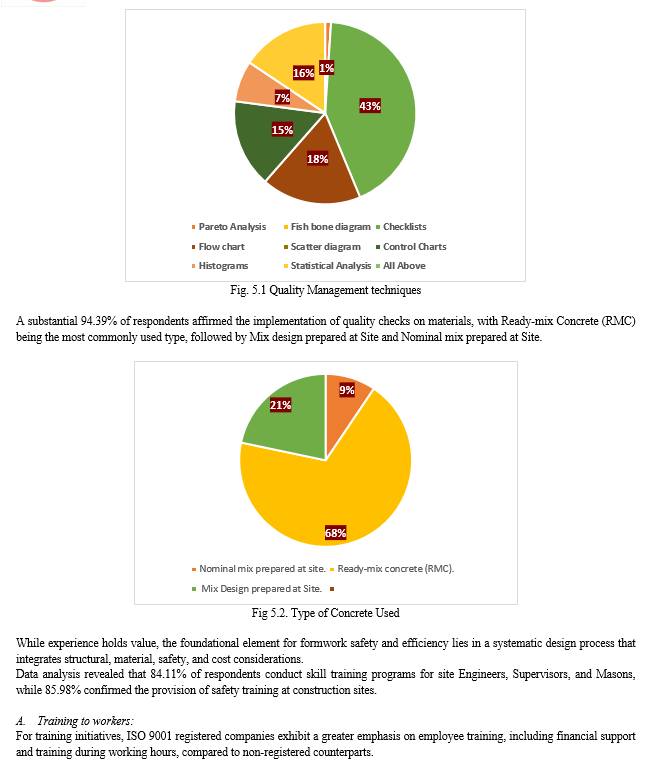

Respondents identified the most crucial quantity management technique at construction sites as the Check List, followed by Flow Charts, Statistical Analysis, Control Charts, Histograms, and Pareto Analysis.

Conclusion

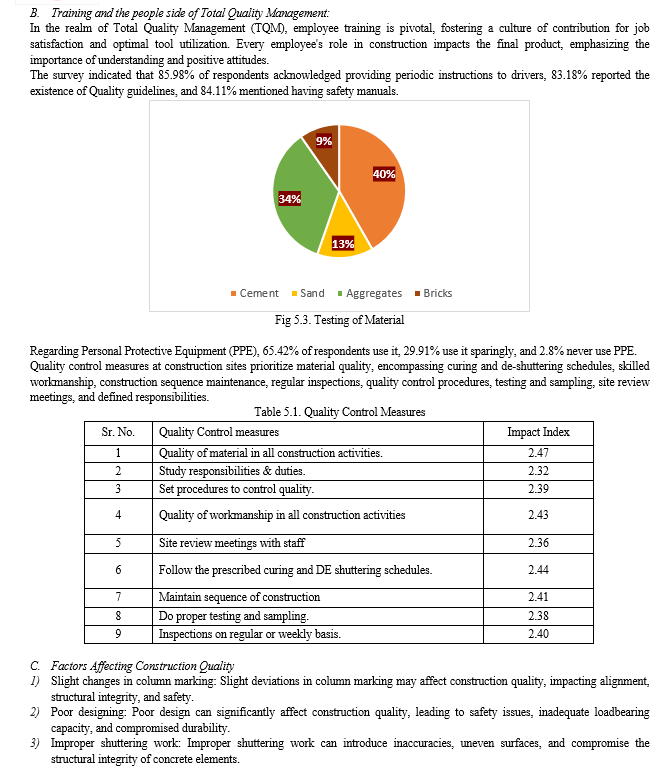

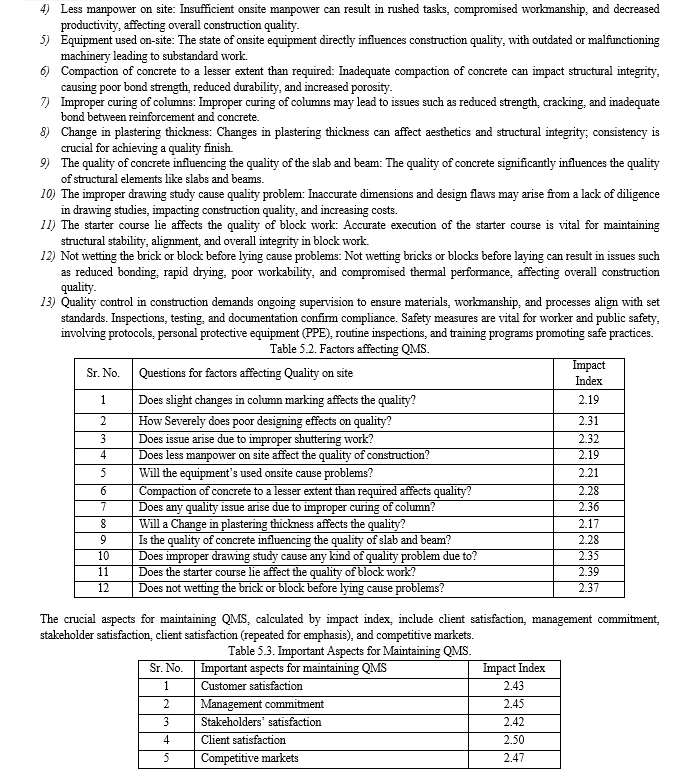

In conclusion, the extensive survey involving 107 participants in the construction industry has yielded valuable insights into quality management techniques, training programs, factors influencing construction quality, and the significance of a quality management system (QMS). The results illuminate key trends and practices, providing a nuanced perspective on both positive and challenging aspects within the construction sector. Respondents overwhelmingly Favor Check Lists as their preferred quality management technique, followed by Flow Charts, Statistical Analysis, Control Charts, Histograms, and Pareto Analysis. This preference lays the groundwork for comprehending the strategies employed to ensure quality at construction sites. Ready Mix Concrete (RMC) dominates the selection of concrete types, with Mix design prepared at Site and Nominal mix prepared at Site being notable alternatives. This information reflects prevailing practices in concrete usage within the industry. The research underscores the importance of skill training programs for site Engineers, Supervisors, and Masons, with a significant majority (84.11%) actively conducting such programs. Furthermore, the strong emphasis on safety training, endorsed by 85.98% of respondents, underscores the industry\'s commitment to a secure working environment. The role of training in Total Quality Management (TQM) is highlighted, acknowledging that successful TQM implementation necessitates thorough employee training. The discussion emphasizes creating a culture fostering continuous improvement, job satisfaction, and a shared commitment to quality throughout the organization. Various factors impacting construction quality are identified, ranging from minor changes in column marking to issues related to poor designing, improper shuttering work, insufficient manpower, and equipment-related concerns. The assigned impact index quantifies the significance of each factor, aiding in prioritizing areas for improvement in construction processes. The research concludes by recognizing the pivotal role of a quality management system in construction projects, with client satisfaction emerging as the primary driver. This perspective is bolstered by factors such as competitive markets, management commitment, customer satisfaction, and stakeholder satisfaction, emphasizing the multifaceted nature of quality management in construction for successful project outcomes. To summarize, these findings contribute to a comprehensive understanding of quality management practices in the construction industry, providing valuable insights for practitioners, researchers, and stakeholders committed to enhancing quality and efficiency in construction projects.

References

[1] Albert P.C. Chan, C.M. Tam, (2000), \"Factors affecting the quality of building projects in Hong Kong\", International Journal of Quality & Reliability Management, 17(4/5), 423-442 [2] Samiaah M. Hassen Al-Tmeemy, Hamzah Abdul- Rahman, Zakaria Harun (2012) “Contractors\' perception of the use of costs of quality system in Malaysian building construction projects”, International Journal of Project Management, Elsevier Science Ltd, 30, 827–838. [3] Ahmad Rashed, Mohammad Othman (2015); “Implementing Quality Management in Construction Projects”, Dubai, United Arab Emirates (UAE), 3 (5), 2329- 2334. [4] Run-Run Dong, (2017): “The application of BIM technology in building construction quality management and talent training”, Eurasia Journal of Mathematics, Science and Technology Education, 13 (7), 4311-4317. [5] Mane P.P. & Patil J.R., (2015), “Quality Management System at Construction Project”, ISSN: 2248-9622, 5 (3), (Part -3), 126-130. [6] Ahmad Rashed, Mohammad Othman (2015); “Implementing Quality Management in Construction Projects”, Dubai, United Arab Emirates (UAE), 3 (5), 2329- 2334. [7] Sergey Lukichev, Marina Romanovich (2016), “The quality management system as a key factor for sustainable development of the construction companies”, Elsevier Science Ltd, 165, 1717-1721. [8] Ivanov Nikolay (2016), “A study on optimization of nonconformities management cost in the quality management system (QMS) of small-sized enterprise of the construction industry”, Elsevier Science Ltd, 153, 228 – 231. [9] Mohd Zaid Malik., Rajiv Banerjee and Syed Aqeel Ahmad (2018), “A review paper on Implementation of Total Quality Management”, International Journal of Recent Scientific Research; 9 (5 (A), 26515-26517. [10] Aawag Mohsen Alawag, Wesam Salah Alaloul (2021): “Total quality management in industrialised building system: Implementation and benefits in construction projects”, Ain Shams Engineering Journal, 14 (2), 101877. [11] Azlan S. Ali, Ismail Rahmat (2010), “The performance measurement of construction projects managed by ISO-certified contractors in Malaysia”, Journal of Retail & Leisure Property, 9, 25 – 35. [12] David Arditi and H Murat Gunaydin, (1997), “Total quality management in the construction process”, International Journal of Project Management, Elsevier Science Ltd and IPMA, 15 (4), 235-243. [13] Junying Loua, Jiang Xu, Kun Wangc (2017), “Study on Construction Quality Control of Urban Complex Project Based on BIM.”, Elsevier Ltd. [14] Longenecker, C.O. and Scazzero, J.A. (1993), \"Total Quality Management from Theory to Practice: A Case Study\", International Journal of Quality & Reliability Management, 10 ( 5 ).

Copyright

Copyright © 2024 Tejal Vishe, Prof. R. Mahadeva Swamy, Dr. Yashvant Patil . This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET63024

Publish Date : 2024-05-31

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online